ADDITIVE MANUFACTURING SERVICES

Short Run Manufacturing

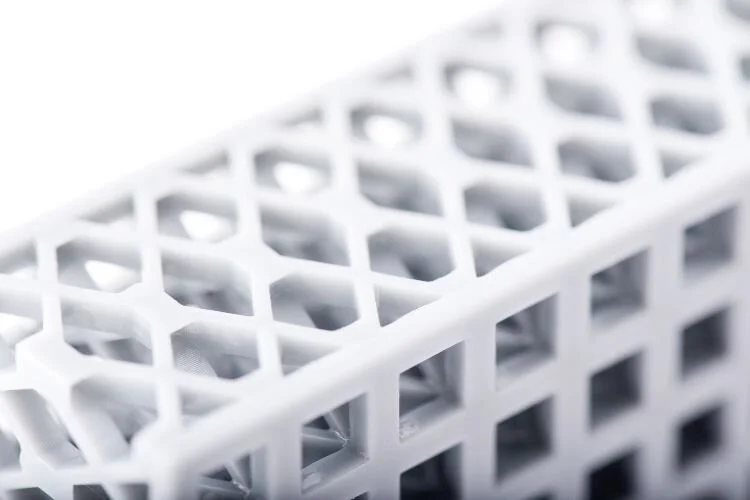

At Primary, we specialize in low volume production of components. Our final parts have incredible material properties and high-quality finishes. As experts in the additive manufacturing process, our short production processes are efficient, fast, and repeatable. We only use the latest additive technologies and the most advanced machines to produce complex parts for a variety of applications and industries.

Rapid Prototyping

Using the most sophisticated additive manufacturing technologies, Primary offers rapid prototyping services for production parts. Whether it is a functional prototype or a visual prototype, Primary has a variety of materials for all needs. With fast turnaround times and quality builds, additive manufacturing brings ideas to life!

Bridge Manufacturing

Transition from rapid prototyping to mass production with additive manufacturing. By using additive manufacturing as a bridge to traditional production, companies can order low-volume runs of their parts at an affordable price—without molds or tooling. With the ability to prototype and test products in the marketplace, companies can perfect their designs before investing in injection molding or machining.

Design Help

Get engineering assistance from an expert in design for additive manufacturing. Our engineers specialize in creating parts for production 3D printing. Anything is possible with additive manufacturing. Whether it is concept or sketch, our team can help you turn your ideas into reality!